Addimetal develops machines and software dedicated to metal additive manufacturing via binder jetting. Our solutions meet industrial requirements for precision, repeatability, and material compatibility (metals and ceramics).

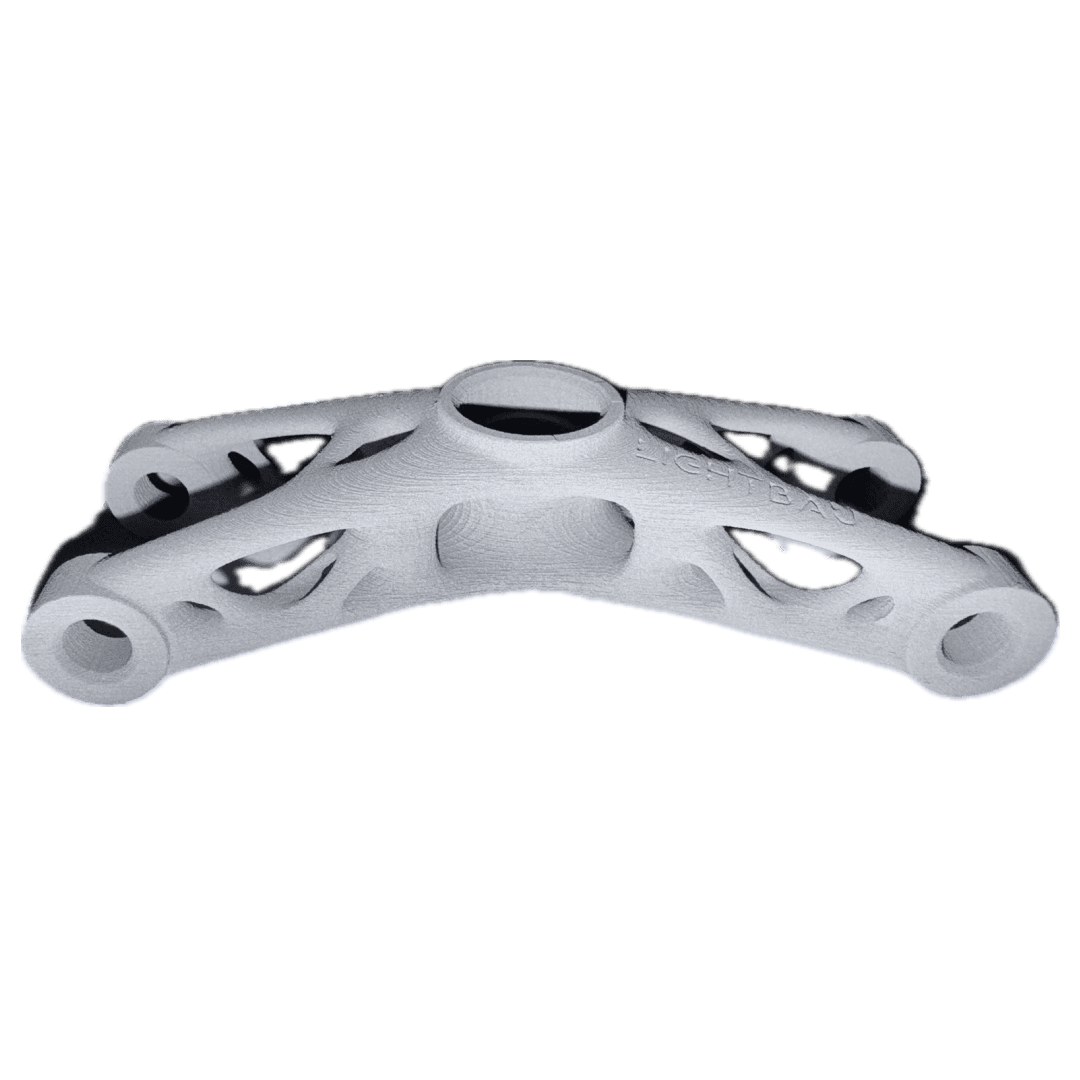

Addimetal provides a 3D printing platform based on binder deposition on a metal or ceramic powder bed. This technology enables the fast production of complex parts, with high precision and multi-material compatibility.

Founded in 2021, the startup ADDIMETAL offers an additive manufacturing (AM) solution based on binder jetting technology on a powder bed.

K2-2 – High-Performance Metal Binder Jetting 3D Printer

Metal 3D Printer using Binder Jetting for R&D

An industrial machine focused on development

By researchers, for industrials

Innovate

Innovate with open parameters in an easy‑to‑use interface, allowing for the testing and qualification of new materials.

Easy to operate and use

Designed to integrate seamlessly into your workflow, while offering the ability to produce complex parts in large quantities at a lower cost.

K2‑2 will help you maximize the efficiency of your manufacturing process

Customizable printing parameters

The K2‑2 machine goes beyond simple layer thickness adjustments.

With our technology, it's easy to control a wide range of advanced parameters, such as layer strategy, binder deposition strategy, speeds and temperatures, controlled atmosphere—ensuring optimal results for every print.

Open to non‑proprietary consumables

If you are seeking maximum flexibility, our K2‑2 machine is the ideal solution.

We allow the use of non‑proprietary consumables, giving you the freedom to choose the materials or binders that best suit your specific needs.

This compatibility ensures great flexibility in your manufacturing projects and optimizes your production processes.

Create

Create with ease using a smart machine that implements a set of innovative technologies.

A high‑performance interface

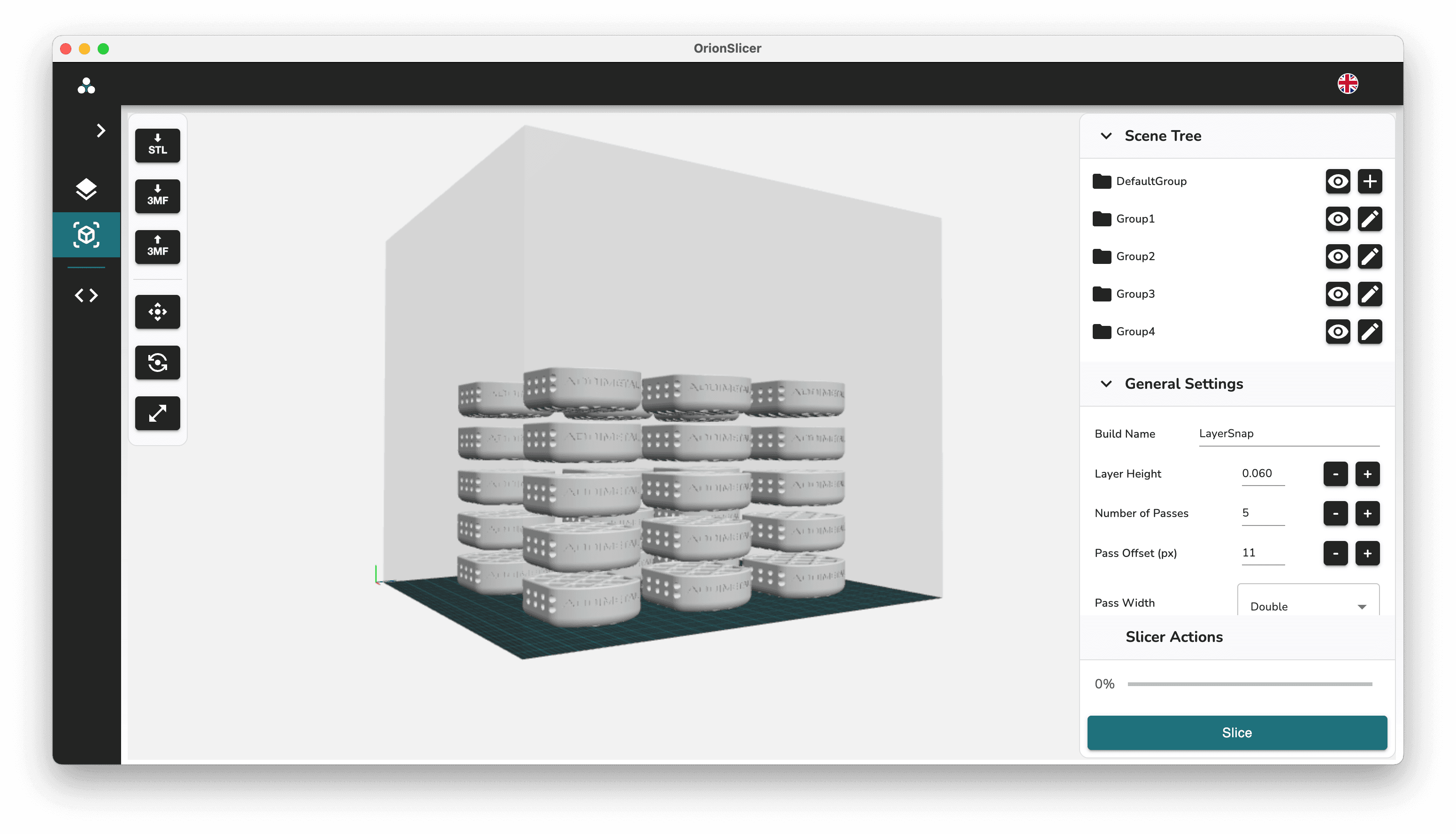

Easily and efficiently create your production files with our Orion software suite.

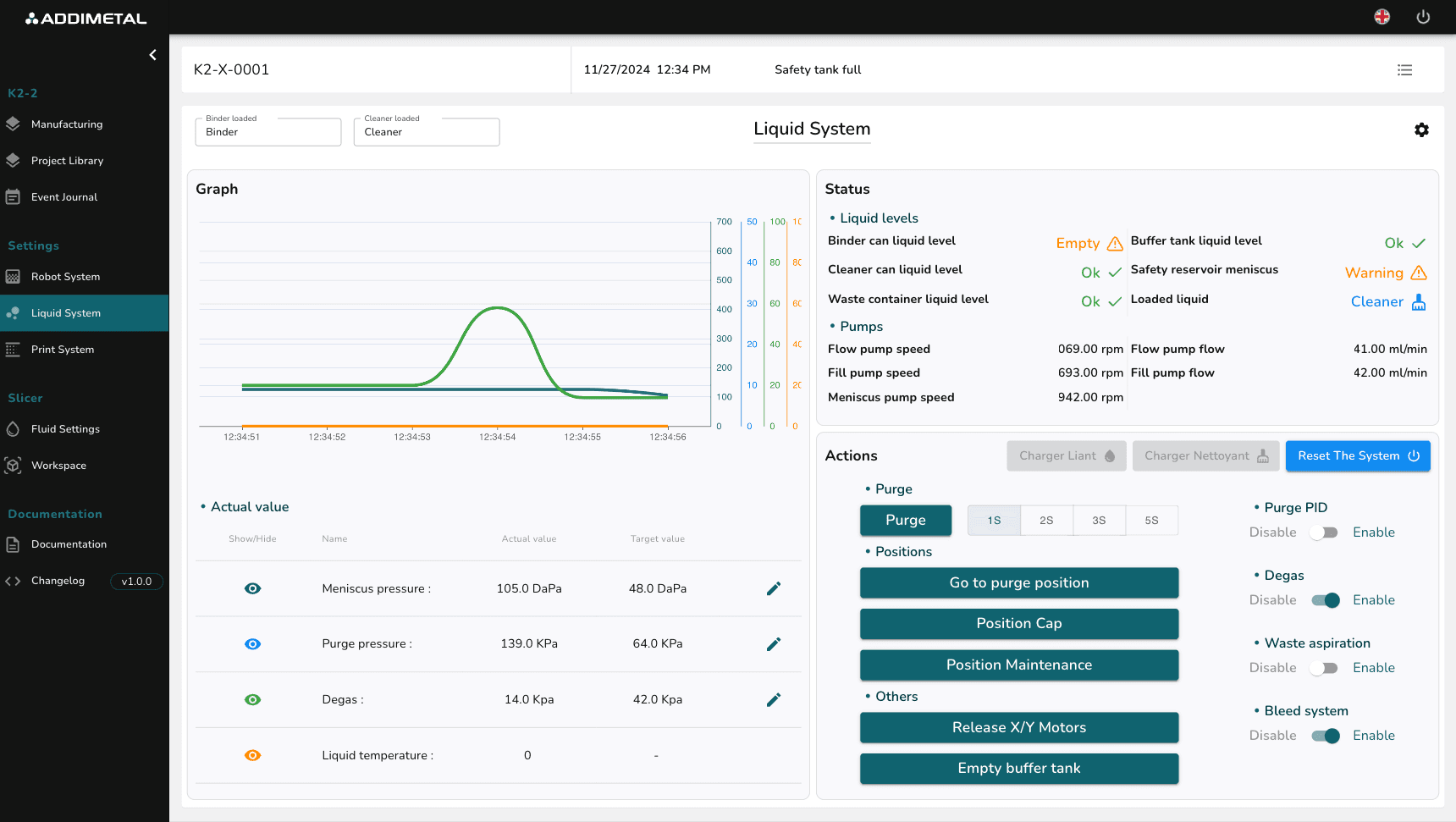

Process control

Controlled environment with visual sensors that allow adjustment of the workspace environment to achieve optimal performance

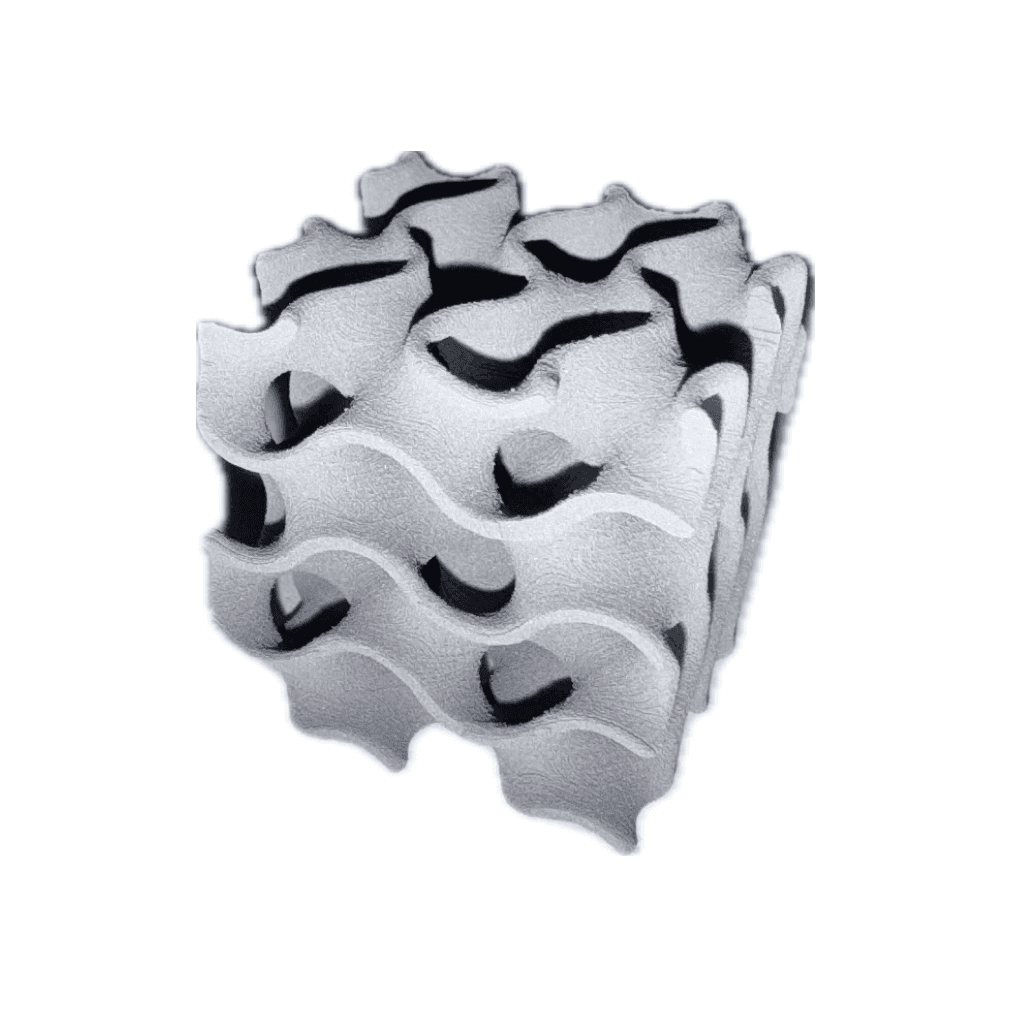

High‑Resolution printing

The K2‑2 is equipped with the highest‑resolution binder jetting system on the market.

With a capability ranging from 360 to 1080 DPI, it offers high‑speed and high‑resolution 3D printing.

This technology enables the creation of metal parts with exceptional precision, ensuring fine details and optimal quality for every print.

Operate

Operate efficiently with a large‑format, high‑capacity industrial print head. Productivity is guaranteed thanks to smooth and efficient operations.

Wide build platform coverage

To ensure seamless printing and optimal quality, the K2‑2 is equipped with the largest print head on the market.

Its width covers more than half the platform, allowing binder to be projected over the entire work surface in one pass.

These technical capabilities enable precise and flexible binder projection.

8L Job Box

200x200x200 mm

The K2‑2 features a comfortable build volume (8L / 200x200x200 mm). The Job Box management system is designed to simplify operator tasks and thus improve productivity.

Layer printing time

Thanks to its advanced design and optimized features, the K2‑2 offers exceptional production speed, allowing you to produce parts with remarkable efficiency and meet the strictest deadlines.

Flexibility and adaptability: various binders

MBJ K2 offers precise thermal control, allowing for the use of different types of binders, tailored to the specific needs of each project.

Our binders are selected for their viscosity, saturation, and debinding properties.

In addition to developing its own high‑performance binders, ADDIMETAL supports its users in the validation and characterization of third‑party binders.

Ergonomic and compact

Its compact design allows it to fit into workspaces by passing through standard doors.

Ease of maintenance Its ergonomic design simplifies maintenance operations, ensuring continuous operation and optimal productivity.

Intuitive use The design was intended to make the user interface user‑friendly, guaranteeing an optimal user experience.

- Hinged doors for easy access to the job box

- Maximum convenience when loading and unloading trays

FOLLOW THE NEWS